ROAD CONSTRUCTION SOLUTIONS

By car, truck or bus, the economy keeps moving on our roads and highways, relying on road construction services to create and maintain the very conduits of a nation’s wellbeing.

Paradox offers road construction services incorporating advanced road building technologies including high-performance geosynthetics approved by the Alberta, Saskatchewan and Manitoba Departments of Transportation. These technologies have been showcased in demonstration projects sponsored by the U.S. DOT- Federal Highway Administration (FHWA), U.S. DOT- Federal Railway Administration (FRA) and United Nations Office of Project Services (UNOPS).

Paradox Road Construction Services include:

- Paved roads & highways

- Unpaved & gravel roads

- Access & heavy haul roads

- Temporary paved/unpaved roads & traffic diversions

Ground transportation of people and goods.

Advantages:

- More durable structure including optimized stress distribution, extends road service life

- Confinement prevents aggregate attrition & less maintenance

- Stronger, reinforced structure allows layer thickness reduction

Benefits:

- Less cost; both in Initial capital cost (CAPEX) and maintenance/operation’s cost (OPEX)

- Reduced construction time

- Allows incorporation of locally available non-graded granular (non-cohesive soils including recycled materials (RAP, recycled concrete etc.)

- Reduced carbon footprint

UNPAVED ROADS

Unpaved Road Design and Tough Cell® Performance

Eighty Percent

It is estimated that 80% of the world’s roadways are unpaved – millions of miles of transportation corridors coping with traffic and climate without the protection of pavement. Bringing modern geotechnical engineering to unpaved road design can add significant durability to any secondary road anywhere in the world.

What’s at Stake

Unlike paved surfaces, gravel roads have a porous wear layer and must maintain a “crown” to prevent water accumulation and erosion. The chief cause of the crown flattening out is a poor base support structure.

Low quality roads require an inordinate amount of material recovery, reshaping and/or amending to ensure intrinsic damage doesn’t occur, all in a continuous effort to avoid:- Ruts

- Washboarding

- Potholes

All of these can take their toll on vehicles and motorists.

Current gravel road design practices

The challenge for a road building company and for currently practiced unpaved road design is to construct a strong sub base and base for the road’s wearing course. Strength below translates to long life for the road as a whole. Creating that strength has been hit and miss using conventional technologies.

Paradox with Tough Cell, however, routinely builds-in that needed strength and increases the durability of gravel roads with geocell soil stabilization technology.Better Roads for the Long Term

When a road subbase and/or base is built with Tough Cell, the modulus of the construction material is greatly increased resulting in significantly improved overall strength in the road structure.

The Tough Cell aggregate confinement of the subbase:

- Gives solid support to the wear layer

- Creates a beam effect of weight distribution

- Restricts road creep

- Cuts material attrition

These qualities together provide near ideal conditions for a long-lasting, low-maintenance gravel road.

Secondary Roads with First Rate Construction

An unpaved road design which includes Tough Cell saves money not only with its reduced maintenance schedule over the long haul but also with initial construction at the outset. Here’s how.

Tough Cell:

- Requires less materials overall

- Improves modulus enough to reduce the road thickness while increasing support.

- Uses lower cost inferior infills

- Works well with weaker granular materials like sand, river rock and RAP.

- Compatible with local material supplies

- Keeps transportation costs down.

- Means faster construction – Tough Cell installs quickly but more importantly, the increased modulus means fewer layers (lifts) are required. This leads to:

- Reduced transportation

- Reduced placement

- Reduced compaction

Savings on initial construction is generally 10% at a minimum and often much more. The savings compound with reduced maintenance over the years to come.

Geotechnical Engineering Approach

Paradox Access, with its pedigree of industrial and access road construction services, respects the role that our rural roads and highways play. It’s with that respect that Paradox brings cellular confinement technology and modern geotechnical engineering to a secondary road near you.

Quality unpaved road design is going be needed for the generations ahead. Tough Cell is going to be leading the way.

PAVED ROADS

Tough Cell® – Road Building for Longevity

Our world is constantly in motion, much of it on our streets and highways. For the foreseeable future, paved roads (flexible or rigid) will continue to play a critical role with our growing transportation needs. Erosion control and pavement reinforcement in highway construction gives extra life to our roads.

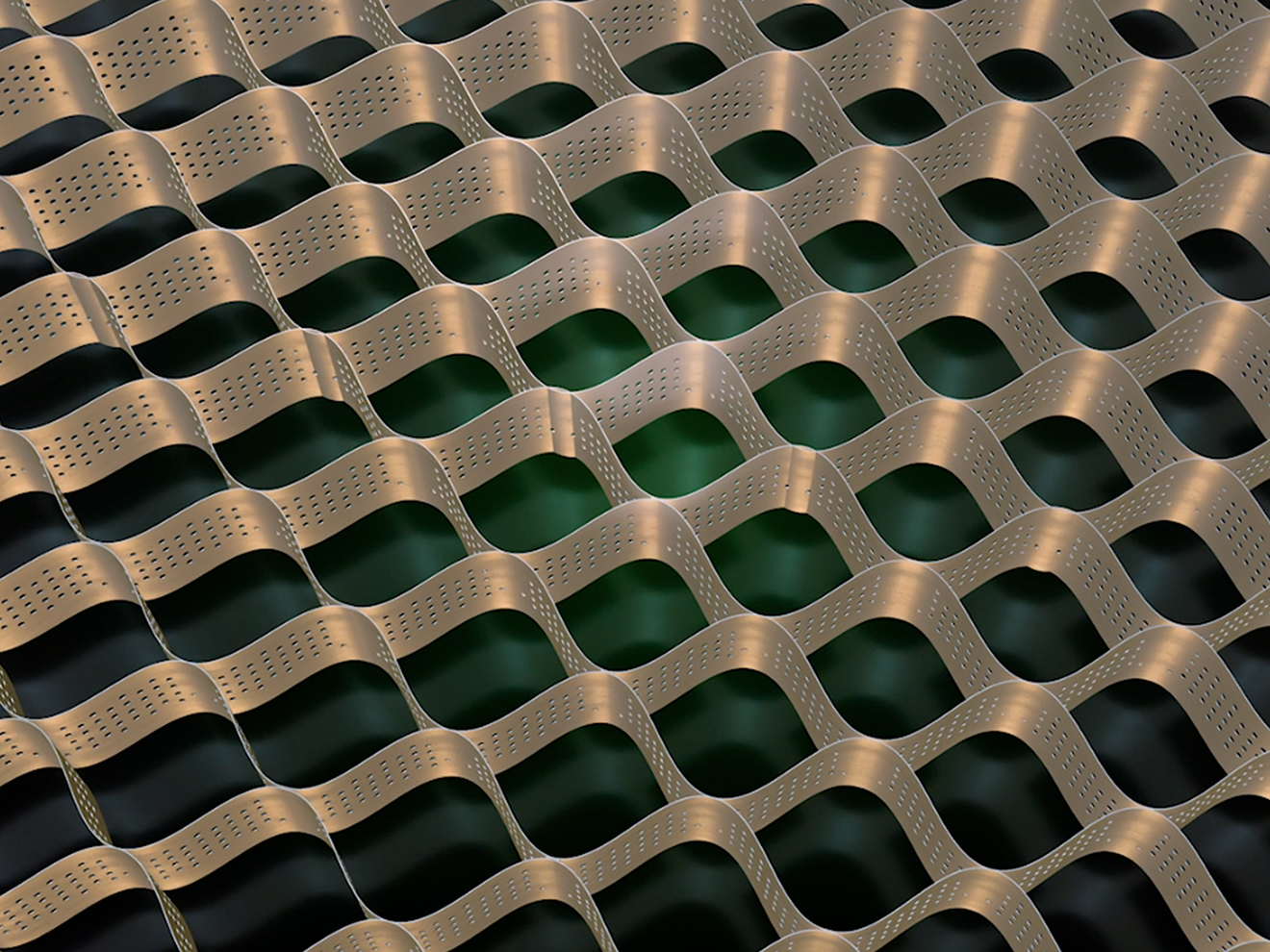

Cellular Confinement Perfected

NPA Geocell technology surpasses the performance of geogrid and also allows incorporation of locally available, weaker granular materials including sand, river rock and recycled concrete/RAP. Tough Cell marks a pinnacle in the evolution of road construction service and technology – a high performance geocell made of a Novel Polymeric Alloy that accelerates road construction and confines and reinforces infills like never before. Initially researched by the US military, geocells and Tough Cell technology now serves civilian traffic on paved roads longer and for less cost.

Building Smarter – Building Better

Paved roads built on a Tough Cell base are smarter and better in many ways. Here are some of the reasons:

Saving Time

- Tough Cell paved roads require less subgrade treatment than conventional construction.

- Priority is removal of organics – subsoil replacement is not necessary

- Excavation can be much less

- Existing strata may be adequate

- Because of increased reinforcement of infill material, the amount of infill needed is greatly reduced. Less infill means:

- less trucking

- less placement

- less compaction

- The stronger sub base usually means the pavement layer can be 20-30% thinner.

- Fewer layers to place and compact is another time saver.

Saving Money

- Reduced and flexible material requirements

- Cut infill by as much as half

- Use lower grade, less costly infills

- Use recycled material infill

- Reduce road pavement material requirement

Saving the Earth

Aggregate and other building materials are getting increasingly scarce. Most road building company practices demand high-grade or virgin materials and generate excessive greenhouse gas emissions to process them.

- Tough Cell paved roads require less materials than conventional roads.

- 40% less infill in most cases

- The stronger base modulus means a thinner wear layer is possible and recommended. Typically, a 20-30% savings on road pavement material is realized. Often, much more.

- A reduction in material translates into a comparable reduction in equipment time to process it.

- Studies indicate cutting 20% or more CO2emissions from the overall construction process by using Tough Cell.

- Lengthen periods between maintenance activities.

- Wear surface maintenance extended by 2x typically.

- Wear surface replacement extended by 1.5 – 2x can be expected.

- Road base modulus improvement extends base lifespan.

Extending the Maintenance Cycle

A Tough Cell base introduces such a high level of pavement reinforcement that the service life of the pavement layer can be extended many times as long.

Over the expected service life, the road pavement over a Tough Cell road base typically experiences:

- Reduced rutting

- Reduced cracking

- Reduced deformation

These reductions lead to a big increase in the longevity of your maintenance budget and service life of paved roads everywhere.

TEMPORARY ROAD CONSTRUCTION WITHOUT COMPROMISE

Roads are Forever?

Not always. Many activities needing roadways are short-lived and are completed after a brief flurry of intensive work. For these situations, temporary road construction methods are the choice.

No Interruptions

Traffic diversions are sometimes a necessity while improvements or repairs are performed. Even though it’s only for a limited time, halting the movement of vehicles through the area is not an option. A temporary bypass road is the solution.

No Roads

Many organizations faced with remote activity have off-road vehicles and equipment that are built to go where there are no roads. You might wonder “why not just do without roads?”

The main reason is that nature at its wildest can be exceptionally hostile to any transportation. Natural terrain can provide many obstacles to navigation by any type of wheeled vehicles.

The toughest trucks can struggle not to:- Tumble into crevasses

- Get entangled in thick vegetation

- Sink into muddy bogs

- Slide down perilous slopes.

These conditions are challenging, if not impossible, for an ultra-light off-road vehicle to traverse, much less a heavy equipment-laden truck.

Why temporary?

A very compelling reason for temporary roads is the trend to impact all that nature as little as possible. It’s a modern goal to restore the natural state of an area after any type of industry has completed its work.

This includes the roadways used to access the sites. “Reclamation” is now part of most projects and this involves making the roadway “disappear” after the work is done.

Other ways

Conventional road construction services may not be suitable for a temporary roadway. It is costly, may require soil replacement and generally requires a large amount of infill material to be trucked in to make a road surface viable.

And because of the punishing conditions of nature and heavy traffic, maintenance can be prohibitively frequent and expensive.

If you need a temporary road, you can use temporary road construction methods.

Paradox provides two solutions to temporary road construction challenges:

- Temporary matting

- Heavy-duty portable decking

- Made of wood and/or metal

- Placed directly on the grade

- Tough Cell temporary road technology

- Geosynthetic cellular confinement

- Efficient use of resources

- High strength and durability

- Suitable for paved or unpaved surfaces

The Best Ways

The definition of “temporary” in any given situation will dictate the best choice. Paradox is a road building company well versed with all of them.

Matting

If the path required will be very short-lived, temporary road mats may be a suitable choice.

- Inexpensive and can be rented

- Fast to transport and place

- Can adapt to just about any terrain

- Quick to remove

- Rapid reclamation

Any one road mat can be moved or relocated independent of the rest.

This type of temporary roadway may be suitable for short term traffic bypass or access to drilling sites, pipelines and power lines.

Tough Cell

Situations that require a more robust surface that will have a longer service life can benefit from temporary access road construction using Tough Cell, a Paradox specialty. Tough Cell is the choice for durability and safety.

- Engineered for all types of traffic, including heavy haul

- Works on extremely soft and uneven ground

- Rigid structure promotes safer road surface

- Faster, cheaper and more ecological than most conventional temporary roadway construction

Because of their small material footprint, Tough Cell roads can be removed and recycled when the job is done with minimal residue and natural reclamation can follow.

The Final Word on Temporary

A temporary road should not mean compromising on quality and should not be considered as “disposable”. Paradox believes any temporary road construction project should be high quality, durable and safe.

The Green Revolution and Sustainable Development

Global realities and increasing demand for infrastructure development have reshaped priorities of decision-makers, including those responsible for roadway construction. Roads and highways must last longer and cost less in order to meet the challenges of infrastructure development and maintenance of existing infrastructure.

Which road construction service from Paradox can help you?